difference between vacuum and non vacuum autoclaves|vacuum vs non autoclave : Brand The most significant differentiating factor between types of autoclaves is their sterilization method. The two principal types of sterilizers are gravity or vacuum-induced/pre-vacuum. That said some autoclaves use both . $1,672.00

{plog:ftitle_list}

Save on Autoclaves & Accessories at Amazon's Lab Equipment Store, featuring every day low prices on Lab & Scientific Equipment.

The most significant differentiating factor between types of autoclaves is their sterilization method. The two principal types of sterilizers are gravity or vacuum-induced/pre-vacuum. That said some autoclaves use both .

https://tomy.amuzainc.com/Types of AutoclavesAutoclaves function primarily through either gravity or vacuum-induced or pre-vacuum (pre vac) sterilization met. Vacuum autoclave steam circulation . On the other hand, vacuum autoclaving, or pre-vacuum autoclaving, is best used when air is not readily available from the sterilised medium. It commonly sterilises objects such as animal cages, bedding or bandaged surgical kits. Hot press tanks designed to perform vacuum cycles have a vacuum system.The 'N' type autoclave is a non-vacuum option that generates steam from a boiler or generator. It uses displacement to push air from the chamber and achieve the required pressure and temperature for sterilisation.Intended Use: The Autoclaves are intended to sterilize unwrapped solid instruments. and non-porous loads (excluding lumened instruments, and dental handpieces).. Printer - for vacuum & none vacuum models. The optional printer can be purchased with the sterilizer, or could be added by the end user later.

The difference in performance and reduced versatility also lies in how they treat the materials which are loaded into the autoclave’s chamber. During the sterilization cycle, steam is pumped inside the chamber. . Pre-vacuum autoclaves can treat wrapped and unwrapped instruments, porous items, as well as medical textile products. This .

The benefits of vacuum cycles in Type B Autoclaves - Summary. Versatility. Type B autoclaves can handle a wide range of materials, including porous items, which would be challenging with non-vacuum autoclaves. Enhanced Sterilization. Vacuum cycles facilitate the removal of air, ensuring efficient sterilization of even the most intricate .What is the difference between the traditional autoclave and the Class B autoclave? Type B sterilizers, also called pre-vacuum steam sterilizers, are similar to gravity displacement autoclaves in that they use steam under pressure to sterilize contaminated items. They have a pump that creates a vacuum in the chamber to ensure air is removed .

desk top autoclave

validation of n type autoclave

Pre-vacuum autoclaves are designed to deliver deeper sterilization, which is why it is best suited for the above examples we just listed. The high-pressure steam in pre-vac autoclaves can also penetrate hard-to-reach areas for an even more exhaustive cleaning process. Main Difference Between Gravity and Pre-Vacuum Autoclave Class ‘N’ autoclaves are non-vacuum units that work by utilising steam from a boiler or generator and creating a downward displacement, pushing air from the chamber. These autoclaves are able to sterilise solid, unwrapped instruments. When the load has finished, HTM01-05 guidelines state that the items should be aseptically wrapped. .However, only a single-stage pre-vacuum is used here; it is less effective than the vacuum used in class B autoclaves. 3. Class B autoclave. Class B autoclaves are the most advanced steam sterilizers. These are certified MEDICAL DEVICES USED IN BEAUTY PARLOURS, tattoo studios, private dental parlours, even in hospitals and large clinics.What types of Autoclaves (Gravity vs. Vacuum Autoclaves) and their advantages? 1 Minutes | | 0 Comment | 0 Like Autoclaves function primarily through either gravity or vacuum-induced or pre-vacuum (pre vac) sterilization methods, though some types of autoclaves combine both methods to sterilize read more .

In the case of vacuum autoclaves, they require a steam penetration test once a day, using either a Helix device or Bowie and Dick. A printable data logger automatically records and prints out this test. It provides written confirmation of sterilisation times, temperature, and whether the autoclave passed the test successfully.Whether you're sterilizing non-porous items or dealing with challenging porous loads, our range of gravity displacement and pre vacuum autoclaves are designed to meet your specific requirements. With advanced features and reliable performance, our autoclaves ensure optimal steam penetration and air removal, enhancing your sterilization outcomes.

the differences between the major types. Sterilisation using saturated steam kills microorganisms by transferring heat onto the items which are being sterilized, as the . and during and after training of new staff in autoclave operation. Pre-vacuum autoclaves are unique in that they require leakage testing for the chamber (to check the door . An autoclave that allows for “pre-vac” cycles can help with this. An autoclave with a vacuum pump allows you to draw a partial vacuum in the chamber during the initial heating period when the chamber fills with steam. “Pulsing” this vacuum entirely removes pockets of cold air from the chamber that might otherwise linger.

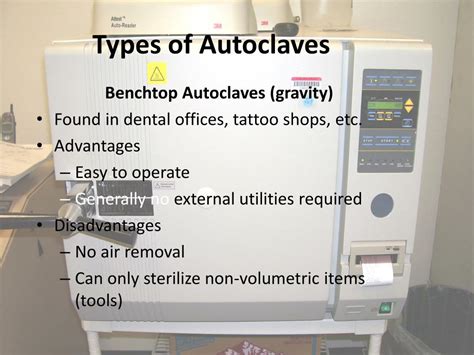

N-Class Autoclaves. Unwrapped, solid instruments and other non-packaged things can be sterilised in N-class autoclaves, sometimes referred to as “Non-vacuum Sterilisers.” In places like research labs and some dentistry offices where hoover systems are not necessary, they are frequently used. The key features of N-Class autoclaves include: We are always asked what the difference between servicing, validation and PSSI (PVI) of benchtop autoclaves is. The servicing aspect includes ensuring the device is mechanically and electrically operating safely and correctly. The autoclave has water and steam passing through it so the plumbing will need attending to.

Non-Hazardous can be sterilized in any of our standard autoclaves without the need for any additional accessories although we would always recommend a pre-post vacuum system to assist with air removal. Hazardous discard however needs deep steam sterilization and exhaust filtration. For this we would recommend an autoclave fitted with a vacuum . The 3 stages of the autoclave process are: 1. The conditioning stage – on a non-vacuum this is when steam circulates the chamber, dislodging and pushing the air it can reach, out. On a vacuum autoclave, this is where the vacuum will forcibly remove all the air before circulating the steam. 2. Exposure stage: This is when the drainage shuts .The vacuum system facilitates more efficient air removal when compared to the gravity method, especially when processing lumened items. During evacuations of the chamber, the pressure in the chamber drops to below atmospheric. . This eliminates sterilizer downtime associated with leaks and saves the time and cost of reprocessing if a positive .

These features can include load sensed process timing, pulsed free-steaming, combined pre-cycle vacuum, and vacuum cooling. Liquids Sterilisers. . Every Priorclave autoclave comes standard with our advanced fully programmable control system, Biomaster® protected antimicrobial surface coatings, free lifetime technical support, and a low . The Different Types of Autoclaves [& How to Choose the Right One] → Steam sterilizers — also known as autoclaves — are an essential piece of equipment in any laboratory, research, or healthcare setting, ensuring sterility for important equipment and instruments.There was no difference between performance of vacuum and non-vacuum autoclaves in dental turbine chamber sterilization, both types performed sterilization properly. Introduction: Dental turbine chamber is a suitable reservoir for living microorganisms, so chamber sterilization is necessary for reducing cross contamination risk. On the other hand, in non-vacuum .Non -Vacuum Autoclave Vacuum Autoclave Reaches 134 degrees, holds for 3 minutes at a 2.25 bar pressure. Cycle lasts 15-20 minutes Reaches 134 degrees, holds for 3 minutes at a 2.25 bar pressure. Cycle lasts for up to 45 minutes Items must be unwrapped and in a single layer on the tray. Items wrapped, and for items with hollow lumens.

There was a significant association between the type of autoclave and the failure rate. It is not clear why. However, it is possible that the non-vacuum type autoclaves were not effective in dislodging air from the items. Overall, fewer than half of .The difference be-tween these two cycles is that the pressure of the vacuum sterilization cycle is set to a value below 0.9bar in the considered phase (Fig.1a), whereas the pressure of the non- . Geometries of a) the vacuum steam sterilizer and b) the non-vacuum steam sterilizer).).. <: (10) + CFD CFD. Sterilizers. steam NCGs Autoclave sterilisation is one of the most effective methods of sterilisation out there. By generating high-pressure steam, pesky microorganisms such as spores can be quickly denatured and killed. Typically, the gravity cycle, vacuum cycle, and liquid cycle are the three most common cycles you will encounter when it comes to autoclave sterilisation.

desktop autoclave tuttnauer

vacuum vs non vacuum autoclave

desmineralizador autoclave

vacuum vs non autoclave

Steam sterilization, or autoclaving, stands as a key defense against microbial contamination. Utilizing steam under pressure, this method effectively sterilizes a wide array of medical tools and supplies.

difference between vacuum and non vacuum autoclaves|vacuum vs non autoclave